Eco Self-Build in Upper Weardale

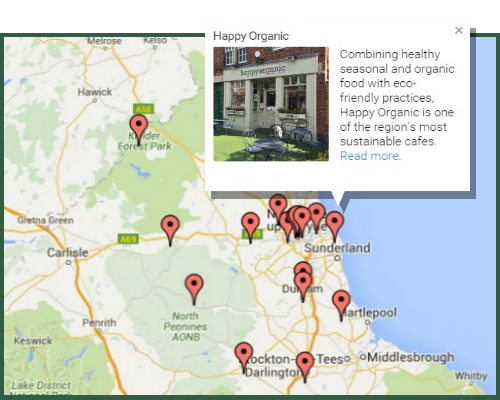

Phil and Joy Newbold have built themselves a compact low-energy home in Upper Weardale which achieves near-Passivhaus standards whilst nestling sympathetically into an Area of Outstanding Natural Beauty.

“You will be most welcome to visit today”, emailed Phil Newbold, “but I have to point out that we have around 150mm of snow lying in the village, with more heavy snow forecast.” Weardale got steadily whiter as I drove up the valley from Durham, and by the time I made it to St. John’s Chapel, I wasn’t going to risk going any further. I parked on the roadside and walked the last quarter of a mile. The only sign of something different in the hamlet of 18 houses was the array of PV and solar-thermal panels on the roof of Greendale Cottage.

Meeting me at the door, Phil welcomed me inside and was soon showing me the thermometer in the dining room. Freezing outside, and 19° C inside. Not bad for a house without a conventional central heating system! Phil attributed the fall in temperature from the prevailing 21°C indoors to sub-zero conditions in the village the night before. I suspect a fascination with monitoring and measuring is all part of life in a low-energy home in much the same way that I’m obsessed with the fuel consumption of my hybrid car.

- Living Room

- Kitchen

- Bedroom

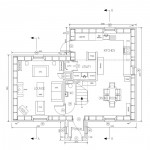

I was shown around the 116m² cottage which has a snug living room, open-plan kitchen-diner and utility space on the ground floor. On the floor above are two bedrooms, two bathrooms and a study for Phil’s business – he’s a certified Passivhaus consultant. A staircase up to the loft reveals a large storage space for much of the behind-the-scenes equipment. Care and attention have obviously been applied to the space planning and interiors which all have a cosy cottage quality well suited to the exterior “Dales vernacular” which was a requirement of the planning process.

Planning Constraints

When Phil and Joy bought the site in early 2012, its existing Planning Permission came with numerous conditions attached. “The Conservation Planning Officer in particular was not interested in the government’s energy conservation agenda at all, just conservation of the local vernacular building style.”The site falls within a Conservation Area and also the North Pennines Area of Outstanding Natural Beauty, and Phil explained that the planners weren’t really interested in his aspirations to build a low-energy house. “The Conservation Planning Officer in particular was not interested in the government’s energy conservation agenda at all, just conservation of the local vernacular building style.” Phil was able to steer the local authority away from their insistence on sliding sash windows which would have made any serious air-tightness measures impossible. As I looked around the village, it seemed that white uPVC casement windows were more common! However, they were stuck with the stone chimneys which will act as significant thermal bridges until Phil lines them internally.

- Ground Floor Plan

- First Floor Plan

- Sections

Construction

The house is constructed using a bespoke timber frame system developed with Swift Timber Homes of Bishop Auckland. Timber frame construction suited this self-build project because it was relatively quick to erect, giving Phil and Joy an opportunity to crack on inside whilst the stone cladding was being erected. As it turned out, 2012 had the wettest summer for 100 years, and the stonework took months!

The ground floor slab sits on 450mm of EPS insulation. The walls comprise double studs separated by OSB straps giving an insulation zone of 280mm between the exterior sheathing board and the internal SmartPly lining. Joy single-handedly applied 60 rolls of Tescon air-tightness tape to the joints, and Phil installed Intello membranes at other key junctions to maintain the airtight barrier.The stud zone was pumped full of Warmcell cellulose insulation recycled from waste paper, and a 50mm service zone was filled with PUR insulation board. Once the insulated doors and triple-glazed windows had been installed, the shell was tested for air-tightness and achieved 0.59 ac/hr, beating the Passivhaus requirement of 0.6 ac/hr, on its first attempt.

- Timber frame being erected

- Airtight grommet and taping to service penetration

- MVHR Unit

Equipment

After a quick dash up the hillside behind the house, to take some photos in the snow, I returned to the fireside to discuss the equipment that Phil has installed. Joy was determined that the new house should have a fire, and the room-sealed wood-burning stove provides some background heat to the living room (approximately 1.5kW), whilst heating the 250L hot water tank and a towel rail in each bathroom (another 8.5kW). Despite all the insulation, the house can’t manage without a heating system entirely, and since they’re not on the natural gas grid, the back-boiler is an easy way to heat water during Winter. In the summer months, most of their hot water is provided by the solar-thermal panels on the roof, topped up by an electric immersion compensated for by a 1.5kW PV array.

A whole house ventilation system (MVHR) recycles heat in the house, whilst bringing in fresh air. Advised by a colleague to buy the best MVHR unit that he could afford, Phil invested in the 94% efficient Paul Novus unit and he doesn’t regret the investment. I couldn’t disagree because not once did I hear any sound coming from the system. He installed the ductwork himself, making good use of the Posi-Joist floors for its distribution.

Budget

Skills Shortage

Living in the House

Two years since moving in, self-build woes are fading from memory and Phil and Joy are enjoying the benefits of their low energy house. Electricity costs are about £35/month and they’re still burning their way through a stack of scrap wood from the build. The high-performance envelope is free from draughts and the triple-glazing excludes noise when the windows are closed. The MVHR extract in the utility room dries laundry nicely overnight using an old-fashioned clothes rack. They haven’t had any problems with overheating, although opening a window is necessary when they have a group of people round. On the other hand, they did discover the inside temperature had dropped to 13°C when they left the house unattended for 7 days and it took another 5 days with a plug-in radiator to bring the house back up to a comfortable level! Such is the fine energy balance in such houses.

The snow had begun falling again when I decided to head down the valley whilst the roads were still clear. I left Phil and Joy impressed with their energy-efficient cottage, not least because it is the product of their own hard work. They’ve been justly recognised with a number of local and national awards and I hope their success will encourage more people to try and achieve the same.

- Design, Project Management and Self Build – Phil Newbold of New Bold Design

- Completion Date: June 2013

- Construction Cost – £180,000

- Primary Energy Demand – 16 kWh/m²/yr

- SAP Energy Rating – 97

- Air Tightness – 0.59 ac/hr

- Ground Floor – 200mm thick self-supporting concrete slab on 450mm Springvale EPS (U-value 0.8 W/m²K)

- Walls – 100mm thick random natural stone, 50mm ventilated cavity, breather membrane on OSB, 280mm timber studs (thermally broken) with Warmcell insulation, SmartPly airtightness layer, 50mm service zone filled with PUR, duplex plasterboard. (U-value 0.12 W/m²K)

- Roof – Natural slates on battens, breather membrane on OSB, 300mm I-beams with Warmcell insulation, Smartply airtightness layer, 50mm service zone filled with PUR, duplex plasterboard. (U-value 0.12 W/m²K)

- Windows and doors – Ecocontract mock-sash tilt & turn triple glazed window from the Green Building Store (U-value = 0.9W/m²K)

- Timber Frame – Swift Timber Frame

- Heating System – Woodfire F12 room-sealed wood-burning stove from Stoves Online

- MVHR System – Paul Novus 300 from the Green Building Store

- Renewables – 1.5kW Panasonic PV array, 4m2 Baxi Solarflo solar-thermal array