Biomass District Heating in Northumberland

A recently installed district heating network is helping to provide a Grade 1 listed country house with sustainable energy from the estate’s woodlands.

Estate owner John Trevelyan talked me through the installation at Netherwitton Hall, near Morpeth, which also provides hot water and heating to four estate cottages. The buildings had, until recently, been heated with independent oil fired boilers, but the introduction of the Renewable Heat Incentive (RHI) encouraged John to invest in the new biomass system. The estate includes 900 acres of plantation forest which is more than enough to provide the 125 tonnes of (wet) timber per year required to keep the boilers ticking over.

The felled timber is stored nearby and allowed to season for 9 months before it’s chipped. Green timber can’t be chipped immediately because of the fire risk from heat caused by composting. When the moisture content has reduced to about 30%, the timber is chipped and delivered, when needed, to a concrete hopper beside the energy centre. Inside, two 100kW Herz boilers maintain a 4000L hot water “battery” at 85 degrees which distributes heat to the buildings through buried flow and return pipework. The paired boilers offer good seasonal efficiency as well as resilience in the event of a breakdown. Each property is fitted with a heat exchanger and a meter. The ash bins only require emptying once a month, and John uses the ash in his garden.

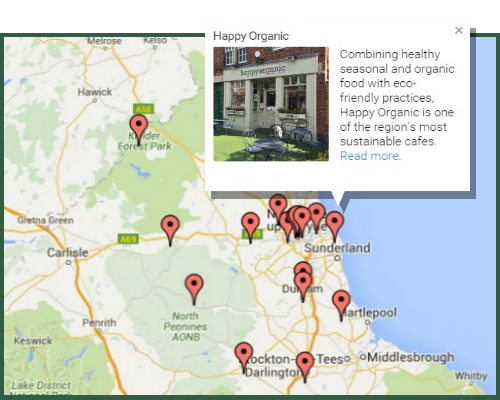

The Grade 1 listed Hall had proven difficult and expensive to heat, and the cost of oil meant that space heating was kept to a bare minimum. This was exacerbated by the limitation on thermal upgrade due to the building’s historic significance. The walls are solid stonework, and large single glazed sash windows leak heat. Energy is supplied to tenants at less than half the price of oil Energy is supplied to tenants at less than half the price of oil, and as landlord, John has seen the benefit of leasing warm and dry properties with fewer boilers to maintain. The scheme has been so successful that he’s completed a second installation to provide heat to eleven houses in the nearby village.

Some have questioned the low-carbon credentials of biomass (1). The Building Regulations, and the RHI both treat biomass as a low-carbon fuel on the assumption that the carbon released on burning can be absorbed by new tree planting. Of course using timber for other purposes, such as construction, locks away the carbon for far longer periods of time. In fact biomass as a fuel source produces carbon emissions equivalent to coal and twice that of natural gas. Biomass shouldn’t be seen as a replacement for energy efficiency.

Here, the heritage significance of the hall severely limits the options for energy efficiency and because the estate is using its own woodland, the transport ‘costs’ are minor. No pellets from Siberia here! Tree felling is part of a commercial plantation operation and only the lowest value timber is chipped for burning, before new saplings are planted. The scheme at Netherwitton Hall demonstrates that biomass has a role to play in the delivery of sustainable energy.

(1) AECB Discussion Paper “Biomass: A Burning Issue” by Nick Grant and Alan Clarke, 2010.

Boiler Installation: The Wood Heating Company

Boilers: 2no. Herz 100kW

Hot Water Battery: 4000L

District Heating Network: Country House and 4 estate cottages, through 50mm insulated pipework.